We are experts in composite manufacturing

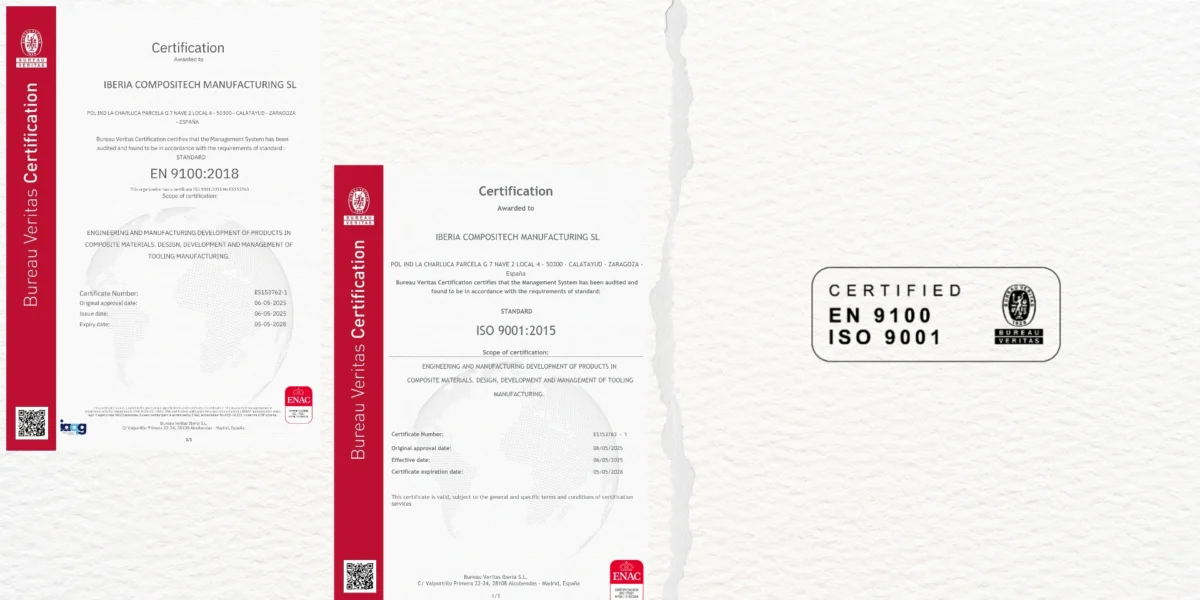

IBERIA COMPOSITECH was born from the perfect combination of knowledge and experience in the handling of composite materials.

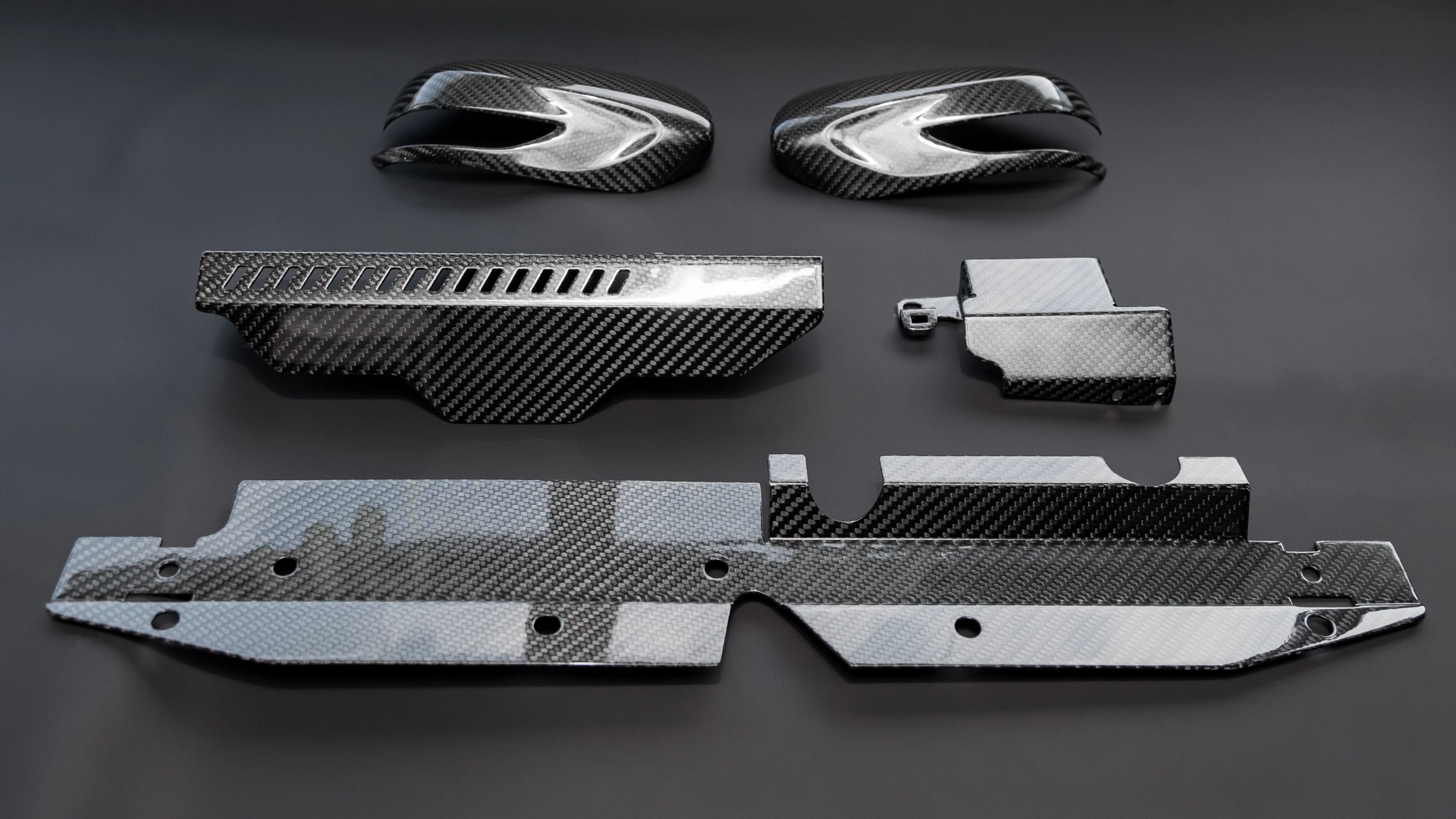

Our commitment extends to demanding markets such as the automotive, aeronautics, nautical, industrial and medical sectors. We master the diversity of composites, specializing in parts made of carbon fibers, glass fiber and aramid fiber.

Our goal is to find the perfect material that fits your engineering projects, providing personalized and quality solutions.

Advanced solutions

Our commitment is to provide solutions and planning, adapted to each stage of your project, thus ensuring a successful and satisfactory development.

Technologies for composites

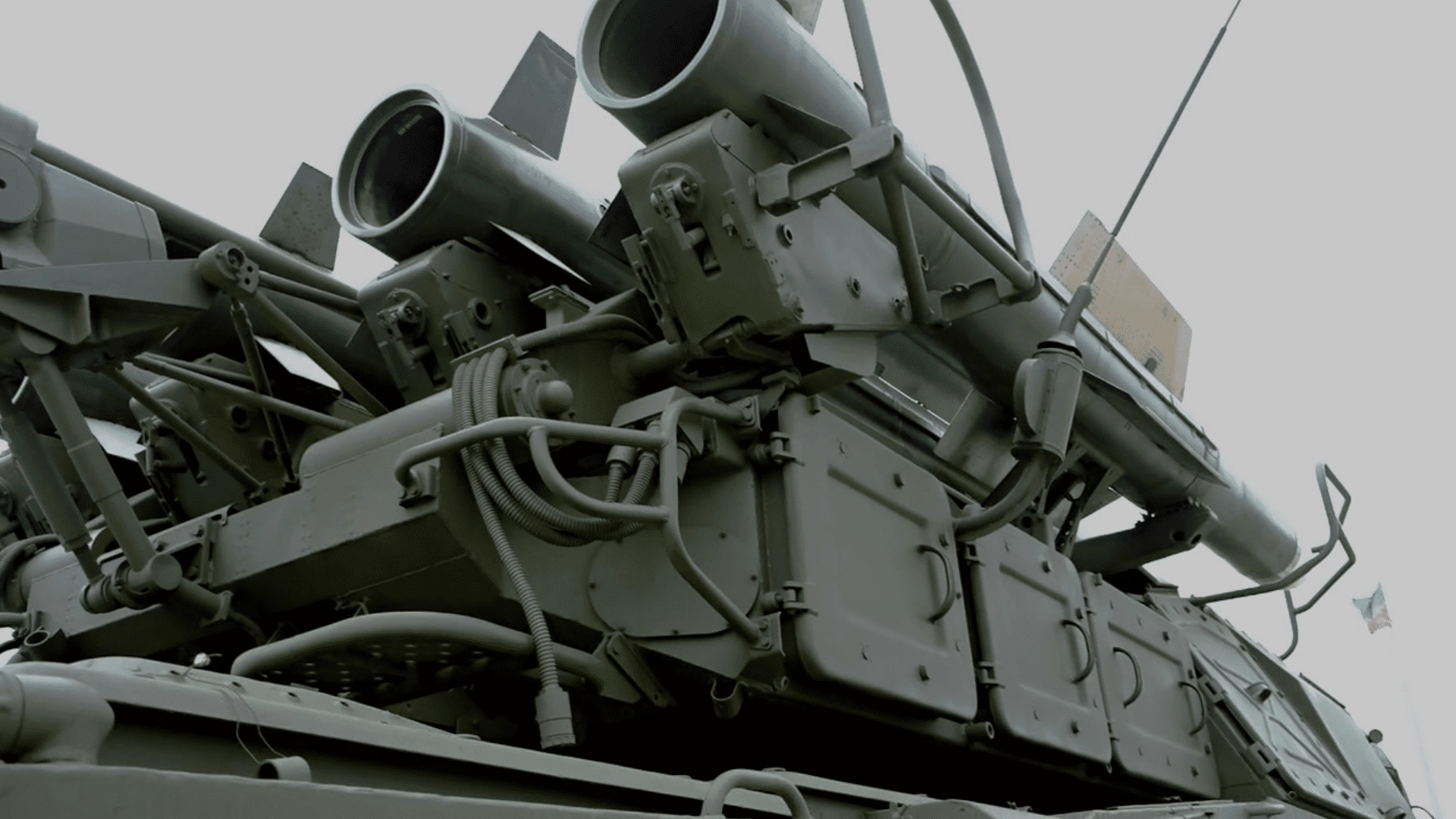

We have specialists and outstanding projects backed by leading companies in various sectors, such as automotive (with a special focus on supercars), industry, aerospace, aeronautics and naval.

Multi-sector experience

We have specialists and outstanding projects backed by leading companies in various sectors, such as automotive (with a special focus on supercars), industry, aerospace, aeronautics and naval.

On our blog we share knowledge, trends, novelties and much more, so you can give free rein to your engineering creativity. We invite you to explore and share our articles, in which we address how composite materials are transforming the world of engineering.