Infusion

Vacuum Assisted Resin Infusion

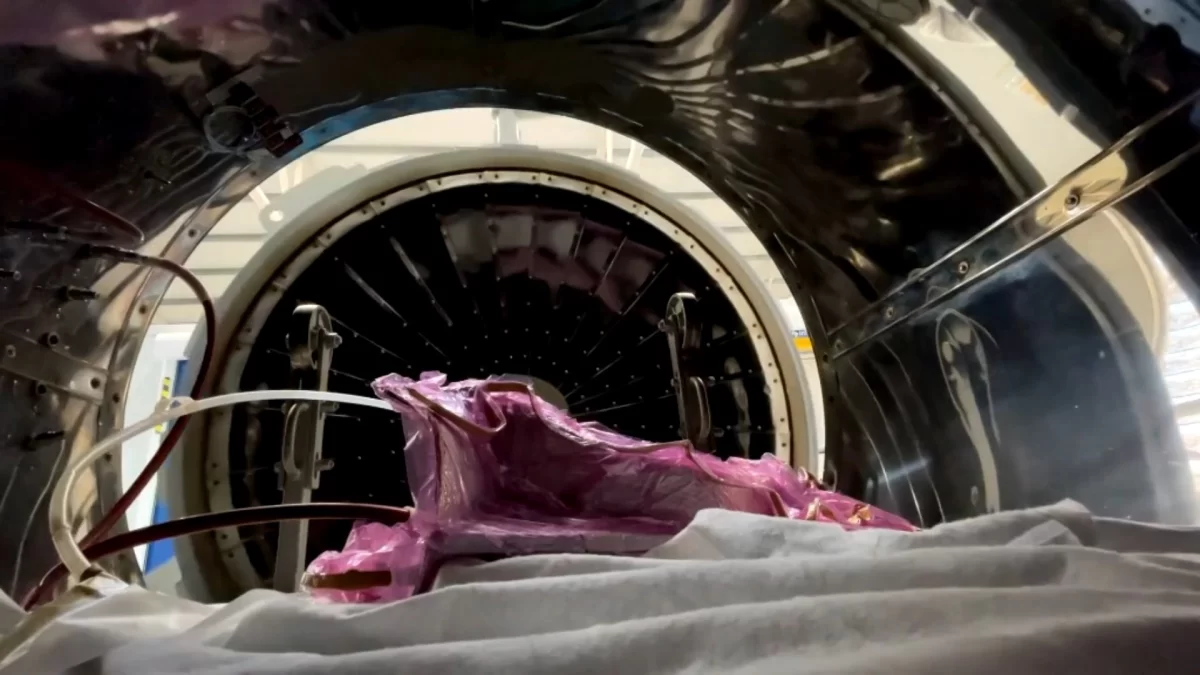

At Iberia Compositech Manufacturing, we use vacuum assisted resin infusion (VARI) to produce high-performance composite components with excellent fibre consolidation and minimal void content.

This process allows us to manufacture large, complex parts with precision, structural integrity and cost efficiency — ideal for aerospace, defence, marine, and industrial applications.

What is Vacuum Assisted Resin Infusion?

Vacuum assisted resin infusion is a closed-mould composite manufacturing process. It involves placing dry fibre reinforcements (such as carbon or glass fibres) into a mould, sealing the system with a vacuum bag, and drawing resin through the fibres using vacuum pressure.

This technique offers several advantages:

- High fibre volume fraction and low void content

- Consistent resin flow for uniform wet-out

- Improved strength-to-weight ratio

- Reduced emissions and cleaner working environment

- Scalable for medium to large part production

Quality You Can Trust

Our expertise in vacuum assisted resin infusion is backed by years of experience and strict quality control protocols. Every step — from lay-up to vacuum setup, resin selection, and cure cycle — is carefully managed to ensure repeatability and structural performance.

Whether we are producing a single prototype or a full production run, we apply the same level of precision and attention to detail. Our team of technicians and engineers is trained to optimise each infusion, reducing waste and improving cycle times.

From Engineering to Execution

At Iberia Compositech, we offer full support throughout the manufacturing process — including design for manufacturability, mould tooling, resin system selection, and post-processing. Thanks to our technical knowledge and hands-on experience, we help our clients bring complex projects to life through efficient and reliable vacuum infusion solutions.