RTM

Resin Transfer Molding (RTM)

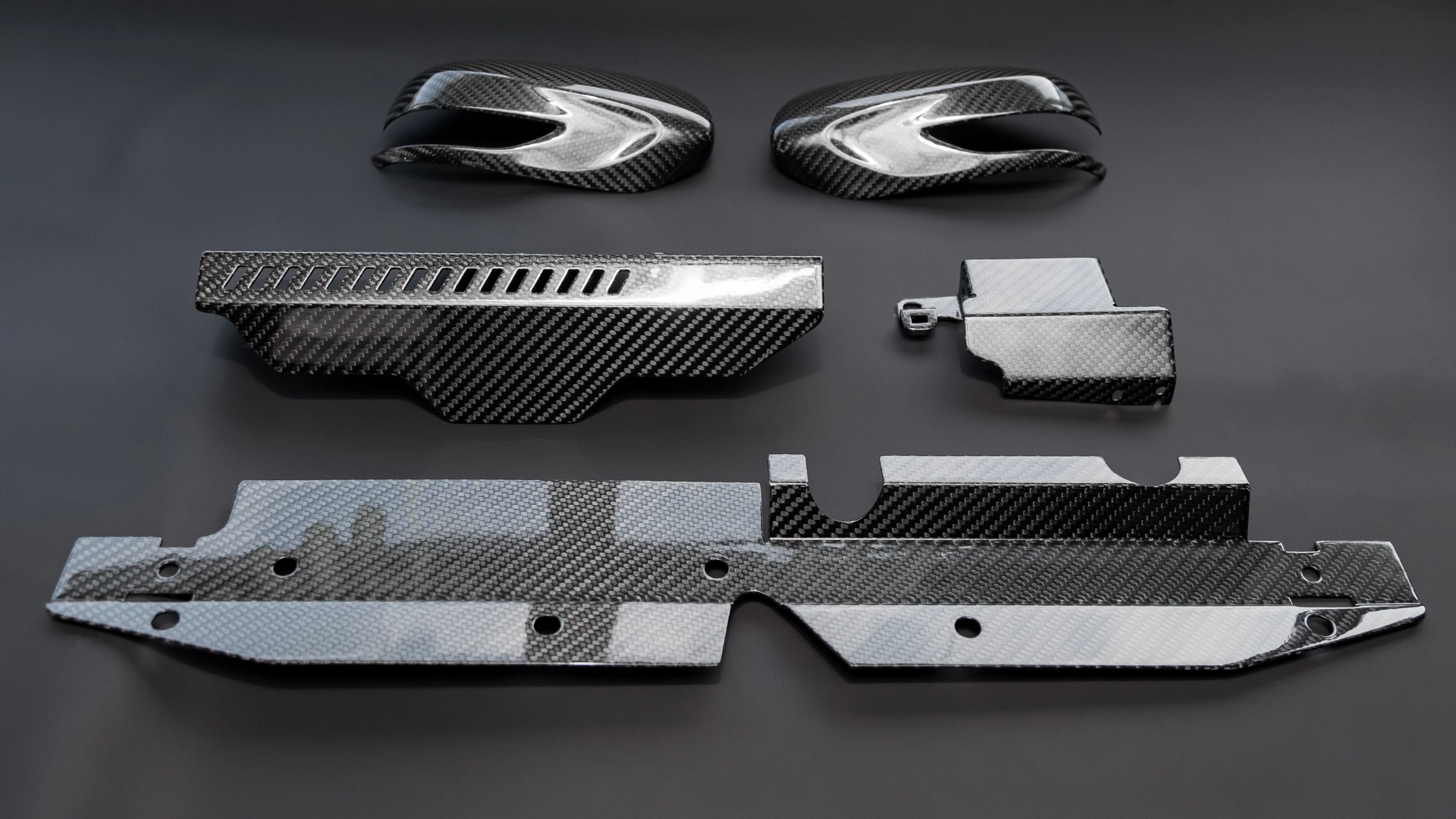

At Iberia Compositech, we offer advanced resin transfer molding (RTM) technology—one of the most efficient and precise processes for manufacturing high-performance composite components.

This method is particularly well-suited for applications that demand structural strength, high-quality surface finishes, and medium to high production volumes.

What is Resin Transfer Molding?

Resin transfer molding is a closed-mold process in which liquid resin is injected under pressure into a mold containing a dry fiber preform (glass, carbon, or other reinforcements).

Once cured, the resulting part features an excellent strength-to-weight ratio, dimensional stability, and a surface ready for painting or additional treatment.

Advantages of RTM at Iberia Compositech

- Superior surface quality – ideal for components where appearance matters.

- Repeatability and precision – excellent dimensional control for medium- to high-volume production.

- Reduced material waste – the closed-mold process ensures efficient resin usage.

- Design flexibility – suitable for complex geometries and various laminate configurations.

- Compatibility with technical fibers – carbon, glass, aramid, and more.

Typical Applications

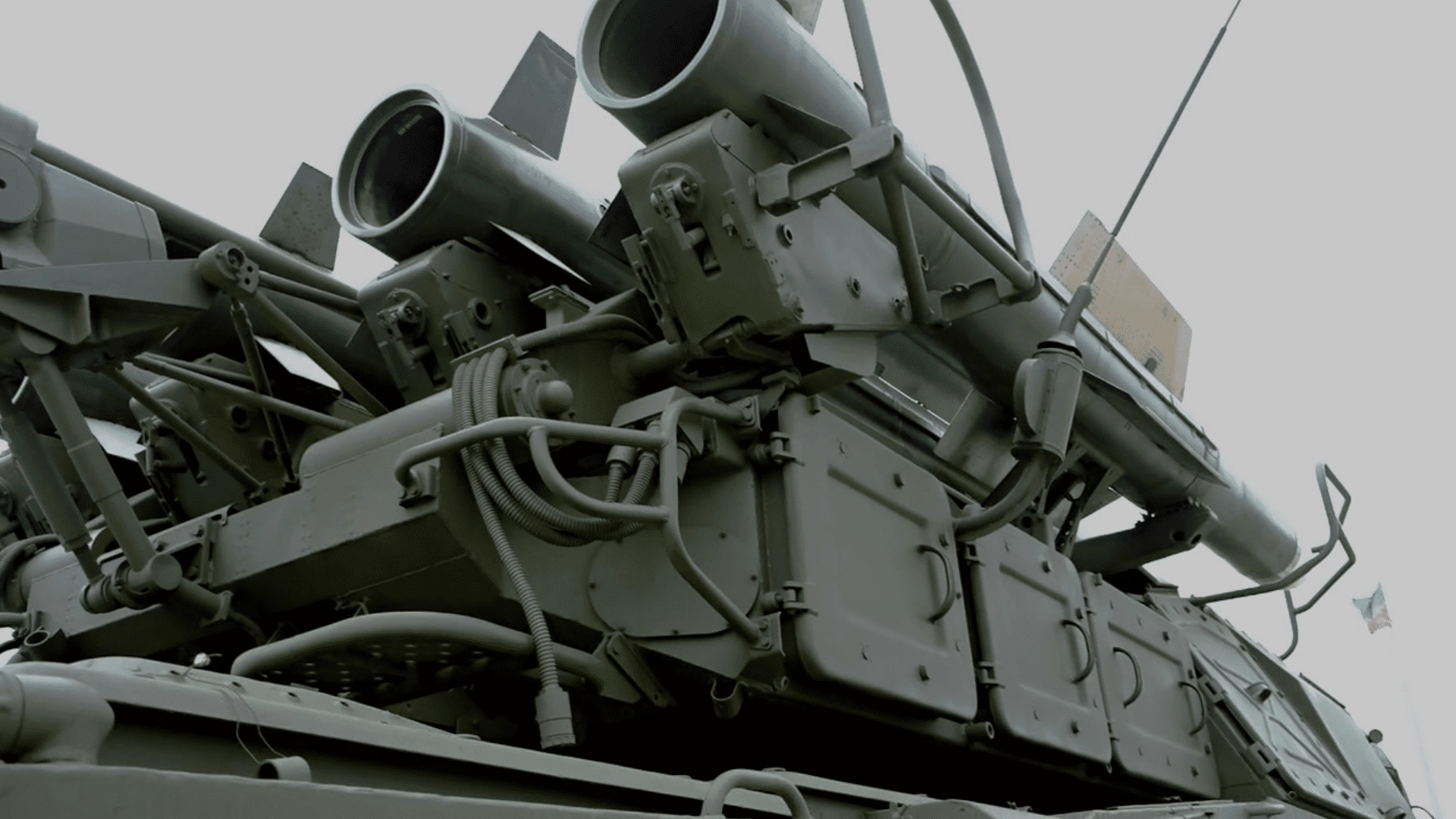

We apply resin transfer molding in industries that demand top-level performance and reliability:

Our RTM Capabilities

Our RTM systems are scalable and adaptable to different part sizes and specifications.

We combine this technology with advanced engineering and cutting-edge materials to deliver optimal results—from prototypes to full-scale production.