Technologies

Technologies – Composite Manufacturing Expertise

At Iberia Compositech Manufacturing, we work with leading composite manufacturing technologies to ensure the highest standards of precision, mechanical performance, and repeatability across all sectors we serve — from aerospace and defence to automotive and motorsport.

Currently, our production focuses on three core manufacturing methods, each selected for its specific technical advantages and applications.

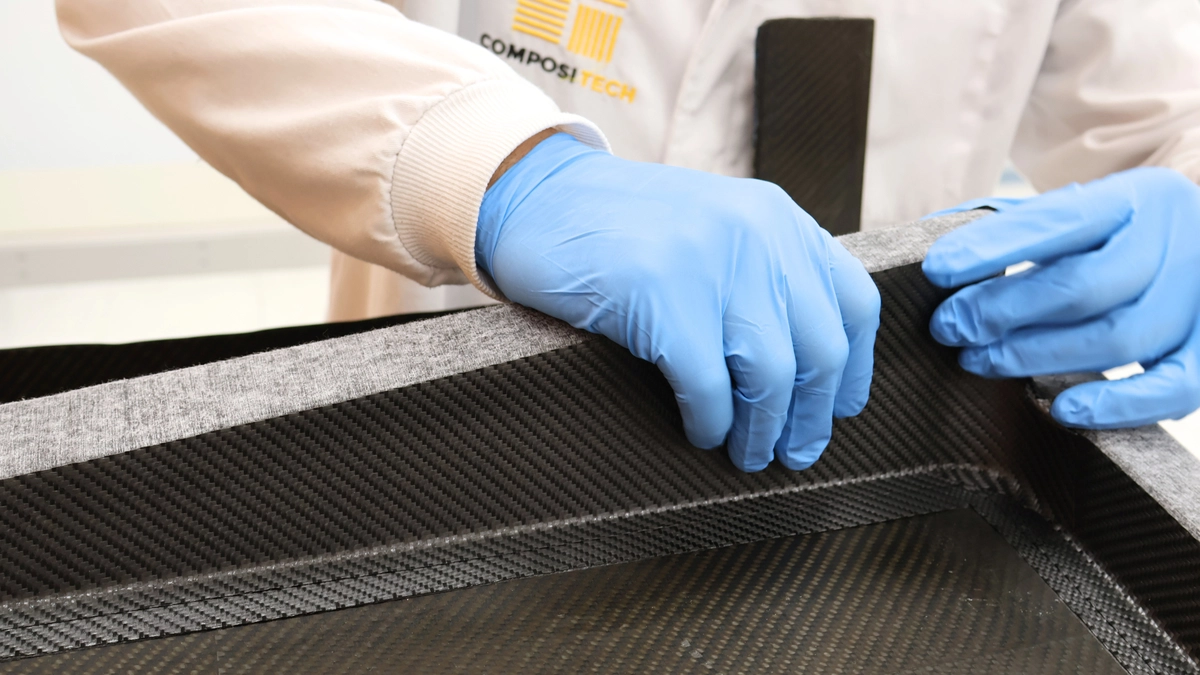

Prepreg

The prepreg process involves the use of pre-impregnated fibre reinforcements (carbon, glass, or aramid) that come already combined with a controlled amount of resin. This method offers:

- Exceptional mechanical properties

- High-quality surface finish

- Consistent fibre-to-resin ratio

- Precise control over layup and curing cycles

Ideal for structural components where weight, strength, and precision are critical, prepreg is the preferred choice in high-performance industries like aerospace and motorsport.

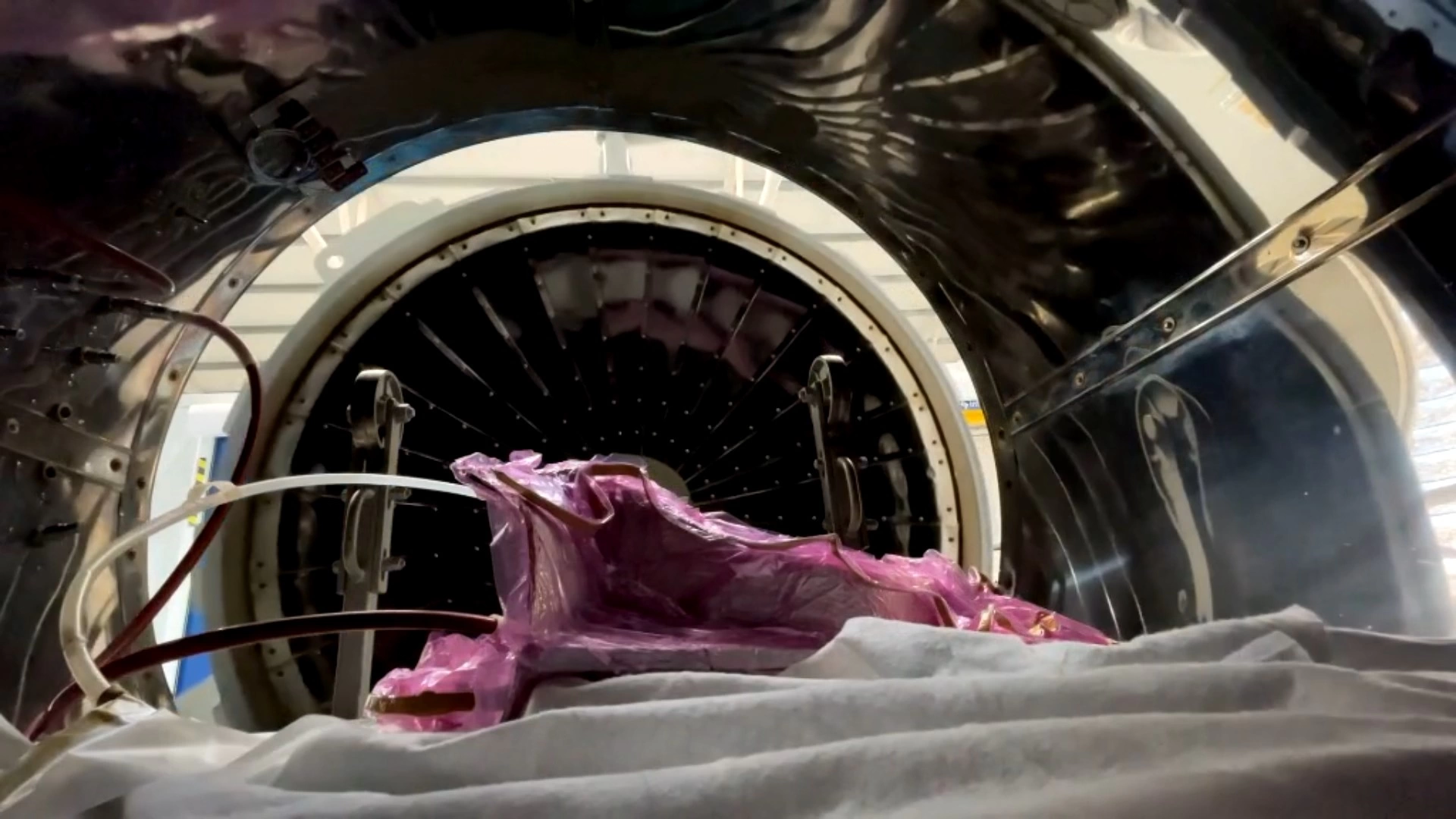

Vacuum Infusion

Vacuum infusion is a closed-mould process in which dry fibres are laid into a mould and then impregnated with resin under vacuum pressure. This technique allows for:

- Excellent resin distribution

- High fibre volume fraction

- Reduced void content

- Cost-effective production for medium-to-large parts

It’s widely used for large-scale components or where complex geometries and light weight are required, such as in automotive panels or aeronautical interiors.

Resin Transfer Moulding (RTM)

RTM is a closed-mould process where dry reinforcements are placed into a mould cavity, which is then injected with resin under pressure. It allows:

- Repeatable, high-volume production

- Good dimensional accuracy

- Smooth internal and external finishes

- Process automation potential

RTM is ideal for components with tight tolerances and aesthetic requirements, frequently used in defence, aerospace interiors, and series production of composite enclosures or structures.

Flexible Technology, Tailored to Your Needs

While these are our core processes today, Iberia Compositech constantly evolves to meet the demands of every project. We analyse the requirements of each part — from performance and weight to budget and scale — and adapt our technology stack accordingly.

Whether you’re developing a one-off prototype or scaling up to serial production, we’ll recommend the right process to get the best results.